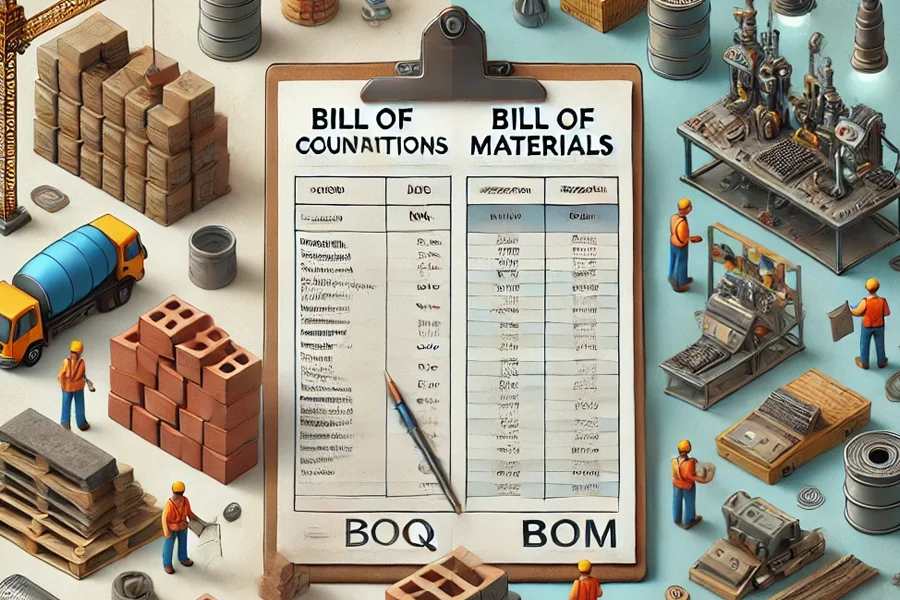

BOQ vs BOM: Understanding the Key Differences

In the worlds of construction, manufacturing, and project management, two important documents help ensure that projects are completed efficiently and cost-effectively: the Bill of Quantities (BOQ) and the Bill of Materials (BOM). While they might seem similar at first glance, they serve distinct purposes. Let’s explore the differences between these two essential documents.

What is a Bill of Quantities (BOQ)?

A Bill of Quantities (BOQ) is a document typically used in the construction industry. It provides a detailed breakdown of the quantities and descriptions of the work required for a project. BOQs are usually prepared by a quantity surveyor or estimator and serve as a crucial tool during the tendering process.

- Purpose: To outline the scope of work, including materials and labor, and provide accurate cost estimates for construction projects.

- Key Components:

- Descriptions of tasks or work sections (e.g., earthworks, masonry).

- Quantities of each task (e.g., cubic meters of concrete, square meters of flooring).

- Associated labor and material costs.

- Usage: BOQs help contractors bid on projects by providing detailed information to ensure accurate and fair pricing. They also serve as a reference for progress payments and tracking during the construction process.

What is a Bill of Materials (BOM)?

A Bill of Materials (BOM) is more commonly used in manufacturing and production. It is a comprehensive list of all the materials, components, and sub-assemblies required to manufacture a product. The BOM acts as a blueprint for the procurement and assembly of goods.

- Purpose: To provide a detailed inventory of the materials and components needed to manufacture a product.

- Key Components:

- Detailed list of raw materials, parts, and components.

- Technical specifications and quantities for each item.

- Information about suppliers, costs, and manufacturing instructions.

- Usage: BOMs help manufacturers plan, procure, and manage inventory. They ensure that all necessary parts are available during the production process and help avoid costly delays.

Both the BOQ and BOM play crucial roles in their respective fields. While the BOQ ensures accurate costing and tendering in construction projects, the BOM guarantees that manufacturing processes run smoothly by providing a comprehensive materials list. Understanding the difference between these two documents can help you better manage projects, whether you’re building a skyscraper or producing a new line of electronics.

Palanivel Muthusamy is a seasoned expert in the Engineering, CAD, CAE, PLM, and PDM domains, boasting over 20 years of experience in project and product engineering within industrial companies. He holds both a Bachelor’s and a Master’s degree in Engineering, complemented by numerous certifications. Palanivel is highly proficient in engineering processes, including engineering change orders, notices, and quality processes, bringing a wealth of knowledge and hands-on expertise to the field.