If you’ve ever worked in manufacturing or product development, you know the frustration of manually transferring data between CAD systems and ERP platforms. It’s tedious, error-prone, and frankly, a waste of your team’s valuable time. But what if I told you there’s a better way?

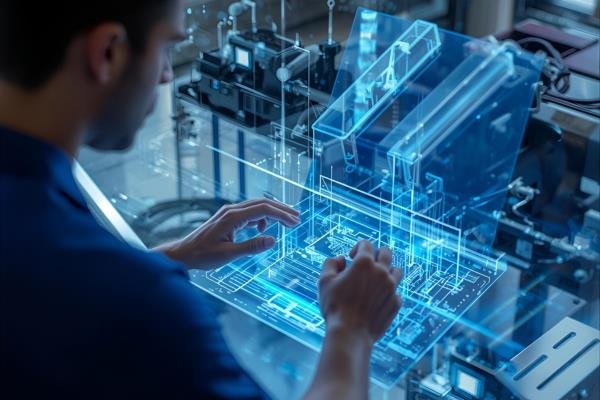

Automating the workflow between Computer-Aided Design (CAD) and Enterprise Resource Planning (ERP) systems isn’t just desirable anymore, it’s becoming essential for companies that want to stay competitive.

Let’s dive into the top five benefits that make this automation a game-changer for your business.

- Eliminate Human Error and Boost Data Accuracy

Your design engineer finishes a complex assembly drawing, and now someone needs to manually extract all the part numbers, quantities, and specifications to input into the ERP system. With hundreds of components, the chances of typos, missed parts, or incorrect quantities are sky-high.

Automated CAD to ERP workflows eliminate this risk entirely. When your CAD system directly communicates with your ERP platform, data flows seamlessly without human intervention. Part numbers, bill of materials (BOM), material specifications, and quantities transfer automatically with 100% accuracy. This means no more scrambling to fix production orders because someone accidentally typed “10” instead of “100” for a critical component.

- Slash Processing Time from Hours to Minutes

Manual data entry between systems is painfully slow. What used to take your team hours, extracting BOMs, cross-referencing part numbers, updating inventory requirements, and creating purchase orders, now happens in minutes.

I’ve seen companies reduce their design-to-production timeline by 40-60% simply by automating these workflows. When engineers make design changes, those updates instantly reflect in procurement, inventory planning, and production scheduling. Your manufacturing team gets real-time visibility into what’s coming down the pipeline, allowing them to prepare materials and resources accordingly.

- Enable Real-Time Collaboration Across Departments

One of the biggest headaches in product development is keeping everyone on the same page. Design makes a change, but procurement doesn’t know until days later. Manufacturing discovers a component shortage, but engineering doesn’t hear about it until it’s too late.

Automated workflows create a single source of truth that connects all your departments. When design updates a CAD model, procurement instantly sees new material requirements. When inventory flags a shortage, engineering gets notified immediately. This real-time collaboration prevents costly delays and keeps projects moving smoothly.

- Scale Your Operations Without Adding Headcount

As your business grows, manual processes become bottlenecks. You can’t keep hiring people just to move data between systems, it’s not sustainable or cost-effective.

Automation scales effortlessly with your business. Whether you’re processing 10 BOMs or 10,000, the automated workflow handles them all with the same speed and accuracy. This scalability is crucial for companies experiencing rapid growth or seasonal fluctuations in demand.

- Unlock Powerful Analytics and Business Intelligence

When your CAD and ERP systems work together seamlessly, you gain unprecedented visibility into your operations. You can track design-to-delivery cycles, identify bottlenecks in your workflow, and make data-driven decisions about resource allocation.

Imagine being able to analyze which design changes most frequently impact production schedules or identifying suppliers who consistently cause delays. This level of insight is only possible when your systems communicate effectively and maintain clean, consistent data.

The IEHUB.AI Advantage

While the benefits are clear, implementing CAD to ERP automation can seem daunting. This is where platforms like IEHUB.AI shine. By providing intelligent integration capabilities, IEHUB.AI helps bridge the gap between your existing CAD and ERP systems without requiring massive infrastructure changes.

The platform’s AI-powered approach can understand complex CAD data structures and intelligently map them to your ERP requirements, making the automation process smoother and more reliable than traditional integration methods.

Getting Started

The transition of automated CAD to ERP workflows doesn’t have to happen overnight. Start with your most critical or high-volume processes, prove the value, and then expand. The key is taking that first step toward automation.

Companies that embrace this automation aren’t just improving efficiency; they’re positioning themselves for sustainable growth in an increasingly competitive market. The question isn’t whether you should automate these workflows, but how quickly can you make it happen.

Ready to transform your design-to-manufacturing process? Technology is here, and the benefits are waiting just a click away at IEHUB.AI.

With nearly two decades of experience in engineering, I bring deep expertise across both EPC (Engineering, Procurement, and Construction) and product-based OEM environments. My core strengths lie in engineering standardization, process optimization, and technical leadership. I have consistently driven excellence through the development and implementation of robust engineering frameworks, delivering value across global industrial projects and complex product lifecycles.